单点抓放实践——使用Hik VisionMaster和MATLAB进行交叉验证

本文是机器视觉2D引导定位的第三篇。主要是基于前两篇的理论,使用 Hik VM 进行实践,计算旋转平移标定的偏移量,并与MATLAB手算的结果进行比对。

过程简介

- 计算仿射变换矩阵

- 计算旋转中心

- 注册基准点

- 计算运行点与基准点的变换参数

在实操上,体现为标定和生产两个流程:

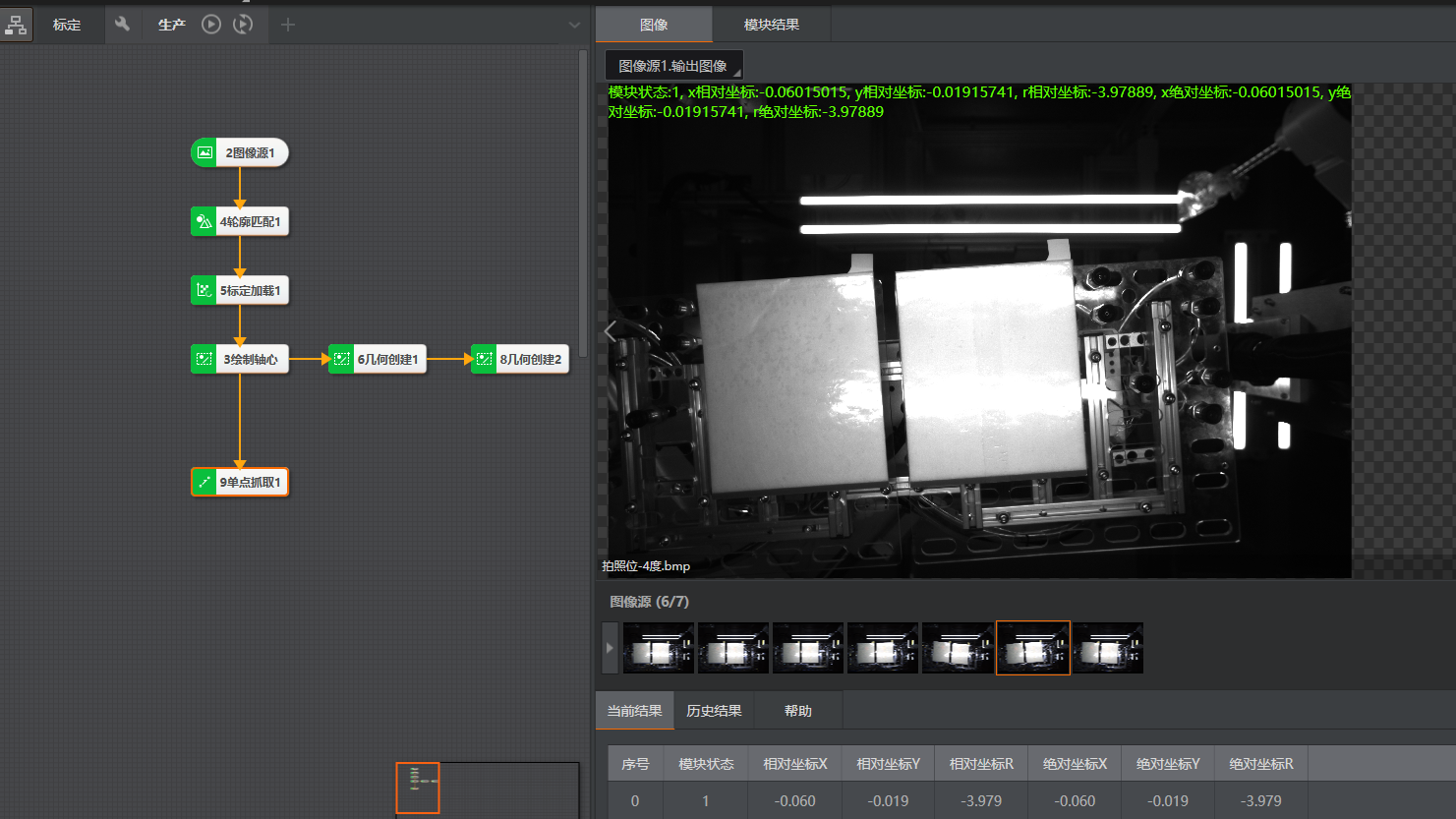

Hik VM 标定与运行

标定

采集图像过程如下:

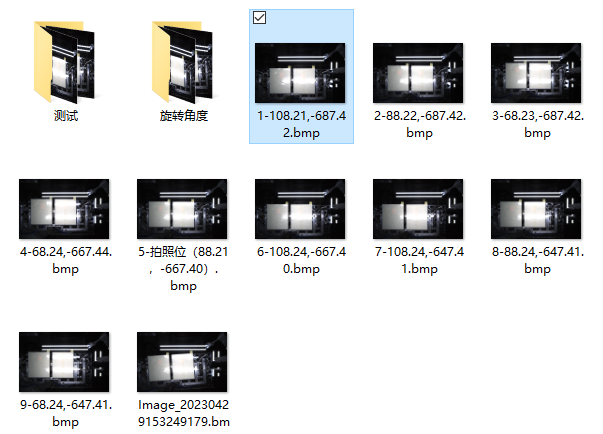

- 九点标定(计算标定矩阵),采集九张图像,同时记录物理坐标

在基准拍照位进行五点拟圆(计算旋转中心),采集五张图像,同时记录物理坐标

Hik VM标定出标定矩阵和旋转中心为:

<?xml version="1.0" encoding="UTF-8"?>

<CalibInfo>

<CalibInputParam>

<CalibParam ParamName="CreateCalibTime" DataType="string">

<ParamValue>2023-06-12 14:22:42</ParamValue>

</CalibParam>

<CalibParam ParamName="CalibType" DataType="string">

<ParamValue>NPointCalib</ParamValue>

</CalibParam>

<CalibParam ParamName="CameraMode" DataType="int">

<ParamValue>CameraStatic</ParamValue>

</CalibParam>

<CalibParam ParamName="TransNum" DataType="int">

<ParamValue>9</ParamValue>

</CalibParam>

<CalibParam ParamName="RotNum" DataType="int">

<ParamValue>3</ParamValue>

</CalibParam>

<CalibParam ParamName="CalibErrStatus" DataType="int">

<ParamValue>0</ParamValue>

</CalibParam>

<CalibParam ParamName="TransError" DataType="float">

<ParamValue>0.61861861</ParamValue>

</CalibParam>

<CalibParam ParamName="RotError" DataType="float">

<ParamValue>0.089774422</ParamValue>

</CalibParam>

<CalibParam ParamName="TransWorldError" DataType="float">

<ParamValue>0.078114673</ParamValue>

</CalibParam>

<CalibParam ParamName="RotWorldError" DataType="float">

<ParamValue>0.011336063</ParamValue>

</CalibParam>

<CalibParam ParamName="PixelPrecisionX" DataType="float">

<ParamValue>0.12673379</ParamValue>

</CalibParam>

<CalibParam ParamName="PixelPrecisionY" DataType="float">

<ParamValue>0.12581174</ParamValue>

</CalibParam>

<CalibParam ParamName="PixelPrecision" DataType="float">

<ParamValue>0.12627275</ParamValue>

</CalibParam>

<CalibPointFListParam ParamName="ImagePointLst" DataType="CalibPointList">

<PointF>

<X>1672.585</X>

<Y>2306.25</Y>

<R>0.016084053</R>

</PointF>

<PointF>

<X>1671.593</X>

<Y>2146.552</Y>

<R>0.065511368</R>

</PointF>

<PointF>

<X>1671.401</X>

<Y>1989.853</Y>

<R>0.096516043</R>

</PointF>

<PointF>

<X>1512.703</X>

<Y>1990.172</Y>

<R>0.059072878</R>

</PointF>

<PointF>

<X>1513.178</X>

<Y>2148.7661</Y>

<R>-0.026686637</R>

</PointF>

<PointF>

<X>1513.7321</X>

<Y>2306.6699</Y>

<R>-0.034523372</R>

</PointF>

<PointF>

<X>1356.887</X>

<Y>2308.7781</Y>

<R>-0.074267119</R>

</PointF>

<PointF>

<X>1356.167</X>

<Y>2149.814</Y>

<R>-0.027513284</R>

</PointF>

<PointF>

<X>1355.734</X>

<Y>1990.894</Y>

<R>0.07842128</R>

</PointF>

<PointF>

<X>1513.2841</X>

<Y>2148.7141</Y>

<R>-0.030053759</R>

</PointF>

<PointF>

<X>1501.818</X>

<Y>2168.0769</Y>

<R>-1.9821</R>

</PointF>

<PointF>

<X>1526.124</X>

<Y>2129.0259</Y>

<R>2.026149</R>

</PointF>

</CalibPointFListParam>

<CalibPointFListParam ParamName="WorldPointLst" DataType="CalibPointList">

<PointF>

<X>108.21</X>

<Y>-687.41998</Y>

<R>0.016000001</R>

</PointF>

<PointF>

<X>88.220001</X>

<Y>-687.41998</Y>

<R>0.066</R>

</PointF>

<PointF>

<X>68.230003</X>

<Y>-687.41998</Y>

<R>0.097000003</R>

</PointF>

<PointF>

<X>68.239998</X>

<Y>-667.44</Y>

<R>0.059</R>

</PointF>

<PointF>

<X>88.209999</X>

<Y>-667.40002</Y>

<R>-0.027000001</R>

</PointF>

<PointF>

<X>108.24</X>

<Y>-667.40002</Y>

<R>-0.035</R>

</PointF>

<PointF>

<X>108.24</X>

<Y>-647.40997</Y>

<R>-0.074000001</R>

</PointF>

<PointF>

<X>88.239998</X>

<Y>-647.40997</Y>

<R>-0.028000001</R>

</PointF>

<PointF>

<X>68.239998</X>

<Y>-647.40997</Y>

<R>0.078000002</R>

</PointF>

<PointF>

<X>88.209999</X>

<Y>-667.40002</Y>

<R>-0.029999999</R>

</PointF>

<PointF>

<X>88.209999</X>

<Y>-667.40002</Y>

<R>-1.982</R>

</PointF>

<PointF>

<X>88.209999</X>

<Y>-667.40002</Y>

<R>2.026</R>

</PointF>

</CalibPointFListParam>

</CalibInputParam>

<CalibOutputParam>

<CalibParam ParamName="RotDirectionState" DataType="int">

<ParamValue>-999</ParamValue>

</CalibParam>

<CalibParam ParamName="IsRightCoorA" DataType="int">

<ParamValue>1</ParamValue>

</CalibParam>

<PointF ParamName="RotCenterImagePoint" DataType="CalibPointF">

<RotCenterImagePointX>2066.9048</RotCenterImagePointX>

<RotCenterImagePointY>2496.908</RotCenterImagePointY>

<RotCenterImageR>-999</RotCenterImageR>

</PointF>

<PointF ParamName="RotCenterWorldPoint" DataType="CalibPointF">

<RotCenterWorldPointX>316.02301</RotCenterWorldPointX>

<RotCenterWorldPointY>-260.5065</RotCenterWorldPointY>

<RotCenterWorldR>-999</RotCenterWorldR>

</PointF>

<CalibFloatListParam ParamName="CalibMatrix" DataType="FloatList">

<ParamValue>0.00091244816</ParamValue>

<ParamValue>0.12581043</ParamValue>

<ParamValue>-316.02301</ParamValue>

<ParamValue>-0.1267305</ParamValue>

<ParamValue>0.00057405682</ParamValue>

<ParamValue>260.5065</ParamValue>

<ParamValue>0</ParamValue>

<ParamValue>0</ParamValue>

<ParamValue>1</ParamValue>

</CalibFloatListParam>

</CalibOutputParam>

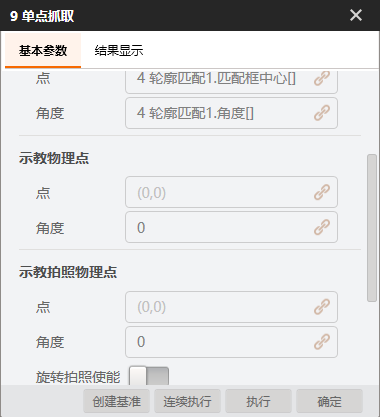

</CalibInfo>对于单点抓取模块,如果我们只关心相对于基准位置的偏移量、而不关心抓件的绝对物理坐标,则示教物理点可以填0:

备注:绝对坐标(X,Y,R)为机构抓取的绝对物理位置,即相对坐标加上示教物理点

如果每次拍照姿态固定,则示教拍照物理点也可填0。

我们选取7张图片进行测试,其图像特征运行点参数(row, col, angle)分别为:

\[

\begin{bmatrix}

1644.710 &2184.197 &0.00374 \\

1683.809 &2183.948 &0.01197 \\

1683.809 &2144.769 &0.00008 \\

1671.944 &2158.424 &-1.97127 \\

1718.255 &2109.892 &5.39912 \\

1660.219 &2172.890 &-3.97881 \\

1696.335 &2131.415 &2.02432 \\

\end{bmatrix}

\]

最终 Hik VM 给出的偏差,以列向量的形式分别为:

\[

\begin{bmatrix}

4.928005 &4.939564 &0 &-0.03858948 &0.1443291 &0.06015015 &0.06814575 \\

4.980583 &0.03192139 &0 &-0.01818466 &0.1011848 &0.01915741 &0.0371885 \\

\end{bmatrix}

\]

使用MATLAB交叉验证

和 Hik VM 一样,我们采取九点标定法计算仿射变换矩阵;而和 Hik VM 不一样的是,为了更准确的计算旋转中心,我们采取五点共圆拟合法,故这里要给出5组旋转轨迹点。

%% 标定数据

cali_data= [

1672.585 2306.25 108.21 -687.42 0

1671.593 2146.552 88.22 -687.42 0

1671.401 1989.853 68.23 -687.42 0

1512.703 1990.172 68.24 -667.44 0

1513.178 2148.766 88.21 -667.4 0

1513.732 2306.67 108.24 -667.4 0

1356.887 2308.778 108.24 -647.41 0

1356.167 2149.814 88.24 -647.41 0

1355.734 1990.894 68.24 -647.41 0

1548.621 2097.044 88.21 -667.4 5.3

1513.284 2148.714 88.21 -667.4 0

1490.558 2188.755 88.21 -667.4 -4

1513.284 2148.714 0 0 0

1501.818 2168.077 0 0 0

1548.621 2097.044 0 0 0

1490.558 2188.755 0 0 0

1526.214 2129.026 0 0 0

];

[H, img_cx, img_cy] = calib_12points(cali_data);

%% 旋转中心

C = H * [img_cx; img_cy; 1];

C = C(1:2)如果你仔细观察的话,会发现这里的 \(H\) 和海康VisionMaster的标定矩阵在第三列上有较大差异。这一点并不影响我们用MATLAB进行最终结果的验证。为了不一次性引入过多细节,我们会在下一篇《单点纠偏》文章中,再仔细讲解海康VisionMaster标定矩阵和标准标定矩阵的差异。

注册基准点:

%% 基准点

p1 = [1683.809 ; 2144.769 ; 1];

q1 = H * p1;

q1 = q1(1:2);

CQ_1 = q1 - C;运行点偏差计算:

%% 运行点

P = [

1644.710 2184.197 0.00374

1683.809 2183.948 0.01197

1683.809 2144.769 0.00008

1671.944 2158.424 -1.97127

1718.255 2109.892 5.39912

1660.219 2172.890 -3.97881

1696.335 2131.415 2.02432

];

%% 偏差计算

Offsets = [];

for p2 = P' % 列向量

% 计算运行点

q2 = H * [ p2(1); p2(2); 1 ]

CQ_2 = q2(1:2, 1) - C;

% 旋转基准点

theta = deg2rad( p2(3,1) );

rotation = [ cos(theta), - sin(theta); sin(theta), cos(theta); ];

CQ_r = rotation * CQ_1;

% 做差

delta = CQ_2 - CQ_r;

Offsets =[ Offsets, delta];

end

disp(Offsets)最终输出结果为:

4.9455 4.9544 0.0001 -0.0477 0.1710 -0.0780 0.0780

4.9789 0.0287 0.0001 -0.0122 0.0875 -0.0066 0.0316可以看到,我们这里使用 MATLAB 手算的结果,与上面 Hik VM 的计算结果非常接近。